Inflatable Formwork Shotcrete Method is Revolutionizing Construction

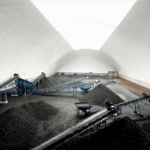

Inflatable formwork shotcrete method represents a groundbreaking approach in construction. It is particularly suitable for applications in grain storage, excavation sites, and other specialized environments. This innovative technique leverages inflatable membranes as temporary molds, facilitating the layered spraying of shotcrete to create robust structural layers. In this article, we will delve into the features, construction process, materials, and advantages of the inflatable formwork shotcrete method.

Key Features of the Inflatable Formwork Shotcrete Method

Material System

This method normally requires the inflatable membranes composed of PVDF-coated polyester fabric. These materials inherently possess excellent air-tightness and thermal insulation properties, characterized by a tensile strength of ≥4000 N/5 cm and an air permeability of ≤0.5 Pa·m³/s. Such specifications are crucial to prevent nitrogen leakages and maintain internal climate conditions.

In addition, reinforcing steel bars must have a tensile strength of ≥400 MPa, while the shotcrete must achieve a minimum strength of ≥8 MPa within the first day. The density of the polyurethane insulation layer should be at least 45 kg/m³, with a bonding strength between the membrane and polyurethane of ≥20 kPa.

Construction Process

The construction employs a layer-by-layer shotcrete application from the bottom up, with each layer limited to a thickness of ≤30 mm. The minimum strength between layers must reach 5 MPa. Furthermore, the circumferential reinforcement overlap must be oriented vertically to the inner surface of the membrane. This maintains an inflation pressure ranging from 550 to 800 Pa and ensures a coordinated pressure-structure control system.

Quality Control

Maintaining structural integrity during construction is paramount. Thus, deviations in vertical alignment should be ≤2.5h/1000, and the tensile strength of joints must achieve at least 80% of the base material. Utilizing advanced digital measurement tools, such as laser distance meters, helps ensure post-construction height deviations are kept within 2% and ≤500 mm.

Application Advantages

Environmentally Friendly and Efficient

Compared to traditional reinforced concrete structures, the inflatable formwork shotcrete method is significantly more eco-friendly, requiring less land and enabling lower-temperature grain storage (below 15°C) and nitrogen gas regulation for pest control.

Seamless Integration

This technique combines inflatable membranes with shotcrete application, resulting in a monolithic structure devoid of seams, thereby enhancing both airtightness and insulation performance. This integration offers improved durability and reduces the likelihood of structural failure.

Official Recognition

The method has gained formal recognition within industry standards, specifically outlined in the Construction and Acceptance Specifications for Inflatable Reinforced Concrete Domes (LS/T 8013-2023), signifying its market maturity and reliability.

Construction Steps of the Inflatable Formwork Shotcrete Method

The construction process can be segmented into several key phases:

Pre-Construction Preparations

- Site Layout: We should clear and level the work surface to ensure proper installation of the inflatable membranes, along with placements for compressors and spray equipment.

- Membrane Installation: The inflatable membrane is deployed and anchored through fixed points, inflated to the designed pressure (typically 550-800 Pa) to form a stable template.

- Reinforcement Installation: Circumferential steel reinforcements are installed following design specifications to ensure vertical alignment with the inner surface of the membrane.

Layered Spraying Operation

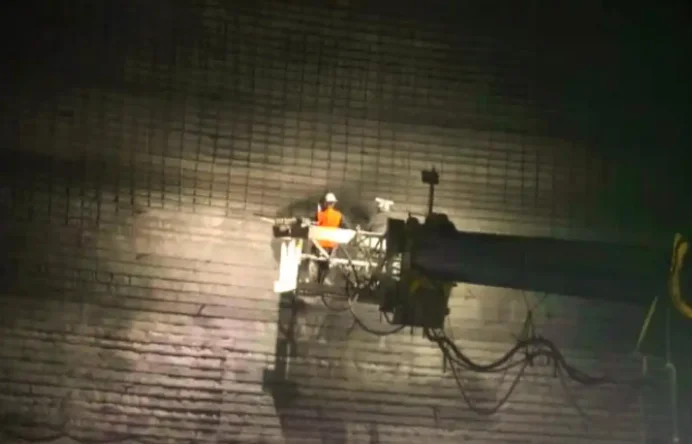

- Initial Closure: A wet spraying method is utilized to apply a 3-5 cm thick layer of shotcrete to seal the inner membrane surface, minimizing dust and enhancing adhesion.

- Layered Construction: Shotcrete is applied in layers, each with a maximum thickness of ≤30 mm. Appropriate intervals must be maintained until the preceding layer reaches a strength of ≥5 MPa, employing spiral-moving spray nozzles positioned 0.6-1.0 m from the target surface.

- Accelerating Agents: Quick-setting agents are introduced at the nozzle to expedite concrete setting time, effectively controlling rebound rates to ≤10%.

Post-Construction Handling and Acceptance

- Surface Finishing and Curing: Following the final set, smoothing out the surface, and water curing must commence for a minimum of 14 days, adjusting methods for low temperatures as needed.

- Quality Assessment: Rigorously examine the structure’s vertical deviations (≤2.5h/1000), thickness (using coring methods), and airtightness (through nitrogen leak tests).

Key Differences in Technique

Comparison to Traditional Spraying

Unlike conventional shotcrete applications, the inflatable method simultaneously controls inflation pressure alongside concrete spraying, minimizing deformation risks in the membrane. Conversely, tunnel spraying mainly emphasizes closing down on rock formations.

Preference for Wet Spraying

Adopting a wet spraying technique lowers airborne dust to below 2 mg/m³, thus enhancing the overall density and quality of the applied shotcrete.

Technical Advantages and Risk Management

Advantages

The inflatable formwork method eliminates the need for conventional formwork, resulting in efficient construction suitable for complex geometric surfaces. The inflatable membrane also creates a stable forming environment, particularly beneficial in cold conditions.

Risk Management

Stringent controls over shotcrete thickness and speed are essential to prevent potential material detachment and membrane failure. We must carefully monitor the inflation pressure to avoid excessive tension, which could lead to structural instability.

Conclusion

Inflatable formwork shotcrete method represents a revolutionary advancement in construction technology, particularly for specialized applications such as grain storage. Its combination of innovative materials, efficient processes, and environmental considerations positions it as a leading choice for future construction projects. It paves the way toward more sustainable and efficient building practices in the construction industry.

Want the Best Solution For Your Project?

CKIC air dome specializes in diverse and cost-effective inflatable dome solutions for various applications, including air domes for military, industrial, recreational, and agricultural use, trusted by a wide range of industries.

Email us to get the most suitable solutions for your project!